Welcome to Tropifruit

At Tropifruit, we have been providing juice concentrates, NFC juices, purees, puree concentrates and many other products for many years to customers in the processing industry around the world. We are committed to fulfill and service any customer requirement backed by our long-term experience, worldwide network and 100% dedication to the task entrusted. We are specialized to providing optimized solutions to bottling companies and manufacturing facilities in terms of product quality, stability, integrity and commitment with your personal service, satisfaction and costs in mind.

High Standards

360° Solutions

Direct Sourcing

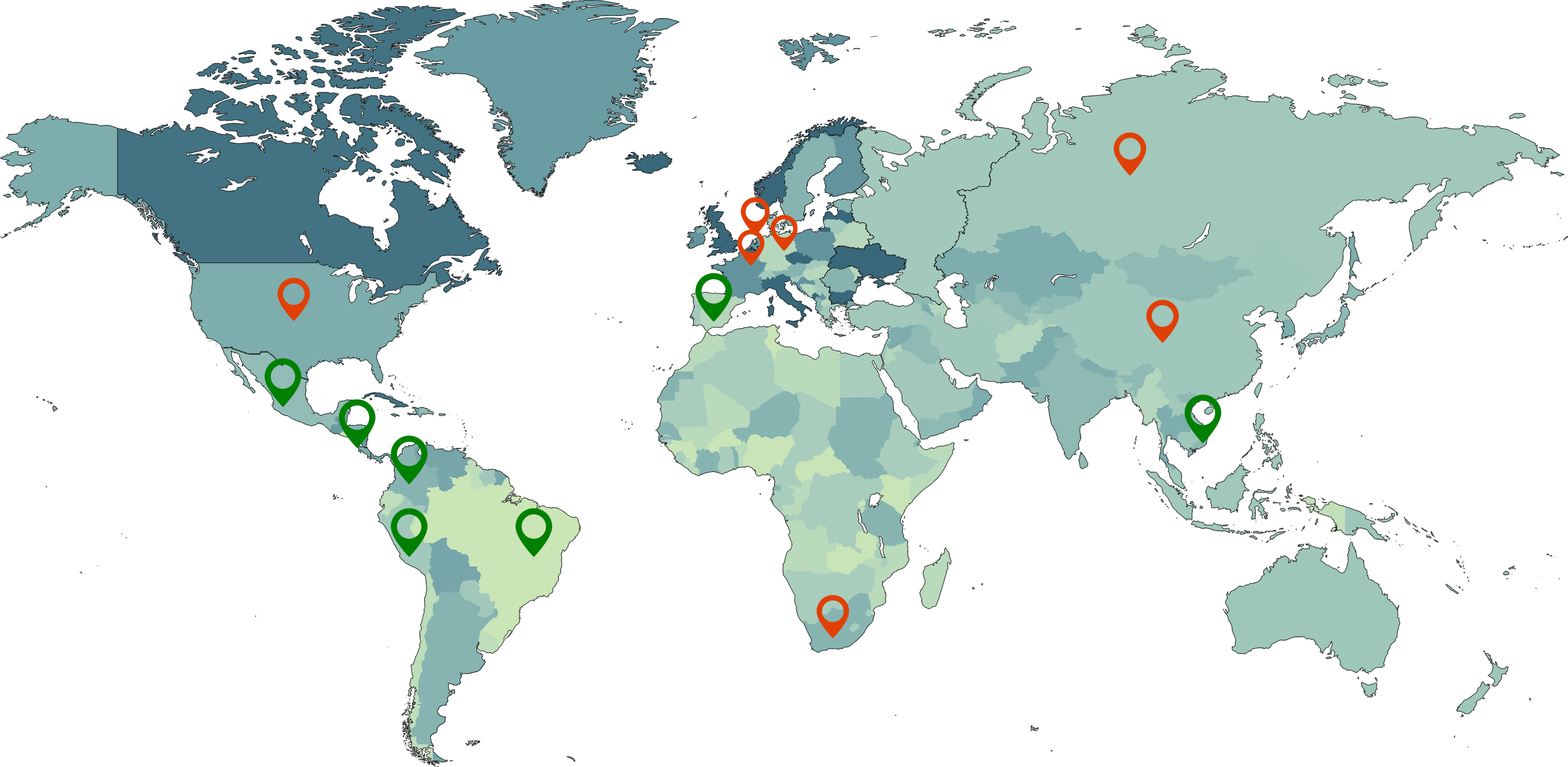

Worldwide Distribution & Trade

- Origins & Cultivations

- Partners & Clients

Your Business, our commitment!

Commit to the LORD whatever you do, and HE will establish your plans.

– Proverbs 16,3 – The Bible